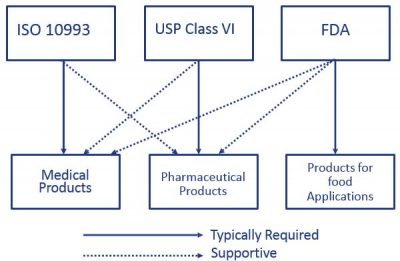

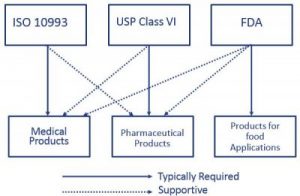

usp class vi vs iso 10993

A more rigorous standard for the biological evaluation of medical devices is ISO-10993. ISO 10993 is designed for medical products that remain permanently or for a very long time in the human body so for shorter applications a USP Class VI or even a lower USP Class certification is often sufficient.

Medical Grade Cyanoacrylate Super Glue Iso 10993 And Usp Class Vi

3D printing of dental and orthopedic surgical guides.

. A more rigorous standard for the biological evaluation of medical devices is ISO-10993. Take an ASTM D2000 call out. My understanding is that a statement in a 510 k that a material is USP Class VI in general will not be accepted by FDA as equivalent to evidence establishing that the nominally corresponding ISO 10993.

Class VI and ISO 10993 are recommendations for testing based on the use of the final device. In fact USP Class VI is sometimes seen as a minimum requirement for biocompatibility. Does your medical molding application require biocompatible rubber.

Usp class vi versus iso 10993 search and take a look to page 8 of the ensinger_medical_brochure_for_2006. USP Class VI and ISO 10993. A selection of Figure 4 VisiJet Accura and DuraForm plastic materials have met the requirements of ISO 10993-5 -10 or USP Class VI testing.

While some of our rubbers can achieve this it is important to understand the customers explicit requirements. Though not a limited series of tests some biocompatibility requirements for medical devices may exceed the testing performed in USP Class VI. Biocompatibility Information for Materials.

Steve Melito August 5 2020. The Right Rheometer for Your Molded Rubber Parts March 30 2022. The most stringent Class VI requires three types of tests.

Other Medical Device Regulations World-Wide. Though not a limited series of tests some biocompatibility requirements for medical devices may exceed the testing performed in usp class vi. That said the lack of risk assessment in USP Class VI can be a problem.

Below youll find a list of all posts that have been tagged as USP Class VI ISO 10993 vs. ISO 134852016 - Medical Device Quality Management Systems. Rob Pruyn August 5 2020 Custom Products Medical Devices Molding Services.

How to Prevent Supply Chain Interruptions. However Class VI also requires subacute toxicity and implantation effects which many ISO 10993 categories do not. Many medical device companies are familiar with USP Class VI but that standard isnt as strict as ISO 10993.

The guidance memo wasis G95-1. Sealable and weldable either pre- or post-sterilization C-Flex 072 provides prolonged pump life Sterilizable by gamma irradiation and autoclave Product Validation Test Summaries available upon request Moldable bondable and formable for single-use assemblies and overmolds Temperature. Unlike other rubber standards theres no one standard that engineers use for an approval.

In fact USP Class VI has been largely superseded since the release of ISO 10993 in 1995. Iso 10993 vs. USP Class VI Testing is only one standard of biocompatibility however.

Though not a limited series of tests some biocompatibility requirements for medical devices may exceed the testing performed in USP Class VI. Inside Rubber Magazine Profiles The Rubber Group June 28 2022. USP Class VI and ISO 10993.

USP class VI versus ISO 10993. While some of our rubbers can achieve this it is important to understand the customers explicit requirements. USP Class VI demands an intracutaneous irritation test.

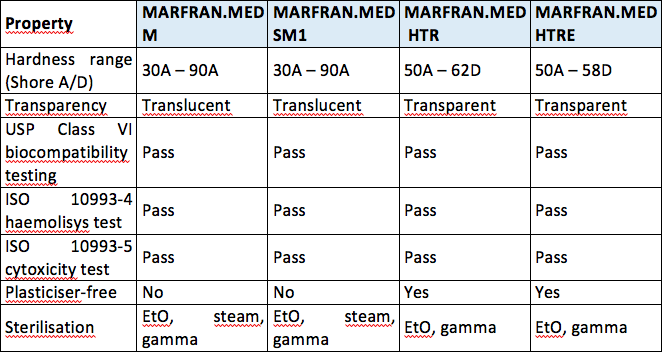

USP class qualification no longer plays any role in medical device materials evaluation. ISO-10993 is a standard that utilizes systemic toxicity and intracutaneous reactivity testing. These international standards refer to the testing requirements for bio-compatibility most commonly used in the medical sector and meet very high standards of manufacture and safety.

USP Class I II - Raw material supplier liability and responsibility. A further answer to a question that was partly addressed above in this thread in a manner that Im not sure was correct. This is their current stance today.

Typically the terms USP Class VI or ISO 10993 materials are used. To begin let us address just what biocompatibility is. Food Grade or USP Class IV Materials for Manufacturing Injectable Products.

USP Class VI vs. Medical Molding and Biocompatible Rubber. So does ISO 10993.

USP Class VI ISO 10993-5 Cytotoxicity In-Vitro Features Benefi ts. In 1995 the FDA adopted ISO 10993 as its biocompatibility approach. That said the lack of risk assessment in USP Class VI can be a problem.

Biocompatibility - USP Class VI vs. This post will take a deeper look at what biocompatibility is and how it is defined by the International Standards Organization. A number of our plastic materials are ISO-10993 or USP Class VI capable.

Then you need to understand the differences. These international standards refer to the testing requirements for bio-compatibility most commonly used in the medical sector and meet very high standards of manufacture and safety. Up-to-date materials manufacturers provide both USP and ISO 10993 test data to support both pharma and device customers.

A rubber compound has set physical parameters it needs to meet. In fact usp class vi has been largely superseded since the release of iso 10993 in 1995. The materials listed below are ideal for.

Regulatory Guidelines For Biocompatibility Safety Testing Mddionline Com

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

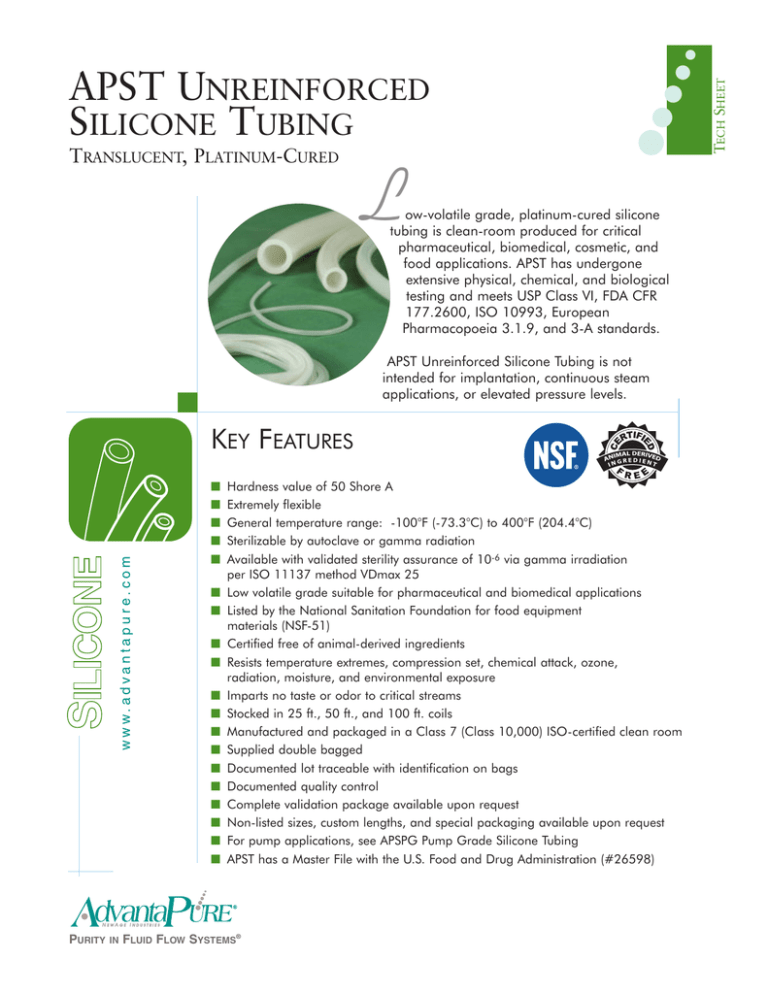

Advantapure Apst Silicone Tubing Translucent Platinum Cured

Material Selection Medical Injection Molding Xcentric Mold

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Pre Colored Medical Abs Compounds For Laser Marking Plastics Technology

Brilliant Mind The World Of Tubing For Medical Use Medical Plastics News

Regulatory Guidelines For Biocompatibility Safety Testing Mddionline Com

Usp Class Vi Certification Presco Marking Products And Engineered Films

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing

Regulatory Guidelines For Biocompatibility Safety Testing Mddionline Com

Usp Class Vi Foster Corporation

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing